“This was the easiest capital project implementation that we’ve ever done!”

Paint Area Manager at a Rancho Cucamonga Facility

Saint Clair Systems’ temperature control system technology helped a company with two different continuous coating lines on the West Coast. Here’s some of how it transformed their processes. They saw:

You can watch the full video here to see how our technology became “an integral part of the painting process.”

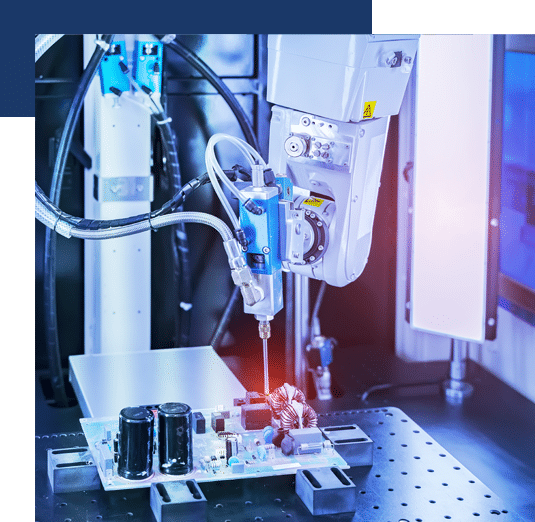

Disruptive Temperature Control Technology Takes Fluid Dispensing Applications to the Next Level

Point-of-Application Outperforms Traditional Methods

Temperature control in fluid dispensing processes is nothing new; many processes attempt to control temperature at the source. Controlling temperature at the drum is simply what’s always been done. And nothing has really challenged that.

Until now.

A lot happens once the process material leaves the drum and makes its way to the paint spray gun. Ambient temperature affects viscosity along its journey, which means variations in viscosity naturally occur once the material leaves the source and makes its way to the point of application. That creates inconsistencies in the texture and quality of the output and has a cascading effect on costly waste, delivery times on specific components, efficiency, and overall profitability.

This does not need to be a cost of doing business.

The Saint Clair Solution

Control Temperature Right at the Point of Application

Instead of controlling temperature at the source (but leaving the material vulnerable to temperature change along its journey to the dispense point), we start right at the point where the fluid is applied. We begin at that point of application, and then work backwards far enough to control the temperature to within +/- 1 degree °F. This removes the issue of temperature change entirely.

There is no other temperature control system that provides this type of consistency, accuracy, and efficiency from the onset.

Overall, by maintaining temperature control at the point of application, manufacturers can improve product quality, increase efficiency and reliability, enhance safety, and realize cost savings.

Point of Use Components for Temperature Control Systems:

Water-Traced Covers

Water Jacketed Coaxial Hoses

Recorable Coaxial Hose Heat Exchanger (patented)

We are globally-recognized experts in temperature and viscosity control with over three decades of experience in the field.

We have seen a large variety of applications and are confident we can find a temperature control solution available for your unique process. To speak with one of our temperature control experts, give us a call.