Ultimate Control: Automated Viscosity Control At The Source. Precise Temperature Control At The Nozzle

Manual monitoring and adjustments to viscosity slow your process down and create unnecessary waste. You’re forced to constantly chase viscosity by taking measurements once an hour, manually making adjustments, and then repeating the process.

We solve that problem with our automated viscosity control system that provides permanent monitoring, real-time measurements, and real-time adjustments. This is keeping viscosity constant at the source.

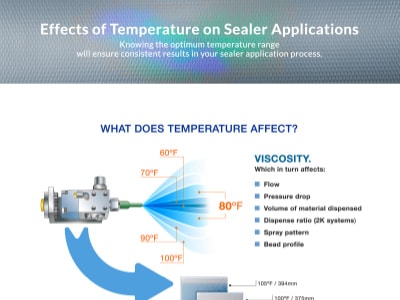

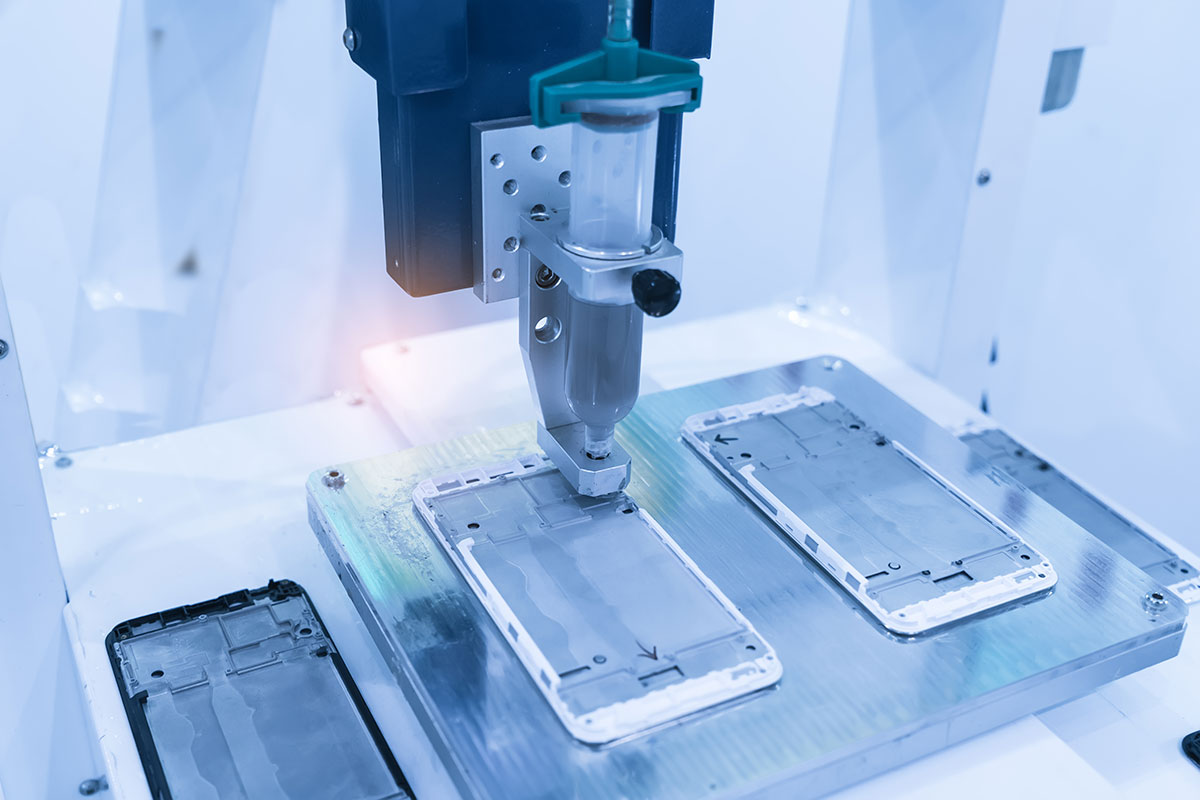

But the material then travels along its path from the source to its final destination - the spray gun. Along the way, your material is subject to changing temperature (i.e., ambient temperature, shear, heat from the pressure, etc.). As temperature is changing in your material, so is the viscosity. The solution is to precisely control temperature at its most critical point in the path - the point of application. Our temperature control system is installed at this end point and maintains temperature at the preset level +/-1℉. This allows the material dispensed to maintain the right viscosity, every time.

What Ultimate Control Means for You

Whether you’re a large operation, a small company, or somewhere in between, to remain competitive requires constantly improving your process. Saint Clair Systems uses lean methodology in addressing fluid dispense systems to continue identifying and eliminating unnecessary inefficiencies. The goal is to streamline and optimize your process in order to cut costs, increase productivity, and improve quality output.

Our Ultimate Control System achieves this for you:

Optimal Temperature Range Will Ensure Consistent Results

Download this guide on learning how optimal temperature range will ensure consistent results in your sealer application process.

Our automated solution provides permanent monitoring, real-time viscosity measurement and adjustments, precise temperature control at the most critical point in your process – the point where your material is dispensed.

Our Ultimate Control solution improves first pass yield results in fluid dispense systems with 99% efficiency. Schedule an evaluation to learn more about how Saint Clair Systems can benefit your process.