In a fluid dispensing process, if temperature changes somewhere along the way, so does viscosity. And a change in viscosity directly affects the consistency and quality of your automotive finishes.

So how do we get around it?

By controlling the temperature and viscosity at the moment fluid is dispensed. We created a point-of-application technology that precisely controls temperature within +/- 1°F of the pre-set temperature. This provides constant viscosity and achieves consistent results in your automotive paint finishing systems.

Control Every Variable in

Your Automotive Painting Process

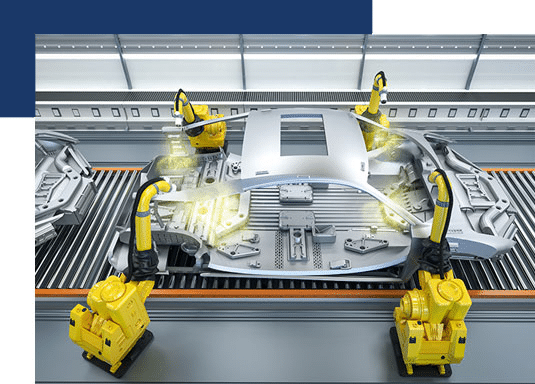

Automotive finishing is a critical step in auto manufacturing. Paint and clear coats have more than just aesthetic value – these protective coatings also shield the vehicle from the elements.

But the effectiveness of this protection depends on quality and consistency in your finishing process. Fluctuations in paint temperature, booth air temperature, humidity, and other variables that affect temperature can lead to bubbles, ripples, thin films, dry spray, craters, or other imperfections that leave cars vulnerable to rust and decay.

Our point-of-application temperature and viscosity control technology eliminates this problem.

Saint Clair Systems has been in the business of cost-effective temperature control solutions for the automotive paint industry for over 32 years. Our team includes internationally-recognized experts in the field of temperature and viscosity control and we’ve seen hundreds of installations in the automotive industry.

We serve automotive manufacturers and suppliers in several areas of the industry:

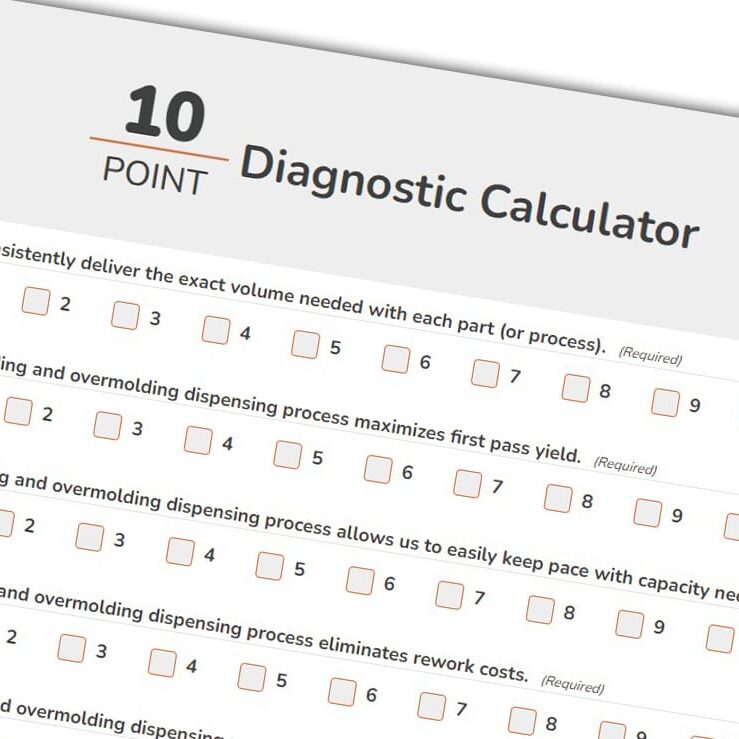

We can evaluate your process, provide you with expert-level analysis, and offer concrete suggestions on improving your process.

Put Simply: Temperature Affects Viscosity, and Viscosity Affects Performance in Your Paint Process.

We understand the role temperature plays in the painting process and are experts at controlling it with precision at the point of application for maximum consistency. Our proprietary thermal sizing tools can assess all factors affecting temperature in your process.

These include:

The Evolution of Paint Temperature Control

In this presentation, we trace the evolution of paint temperature control from its origins to the modern systems of today. Why did it become necessary in the first place? What were the contributing factors, and how did they drive the development of the original systems?

We’ll look at how changes in both paint chemistry and the automotive marketplace transformed the fundamental purpose of temperature control from preserving the paint (protective) to improving finish quality (aesthetic).

Finally, we’ll examine why paint temperature control is still necessary by comparing old approaches to newer temperature control technologies.

Saint Clair Systems can improve orange peel results by at least 1 ACT panel (out of 10). Review research via PCI Magazine that shows how this works when using the BYK Wavescan System.