World-leading coil, sheet, and roll coating companies strive to be the best, both in the quality of their finished product and environmental and social responsibility. In order to be competitive in today’s market, they pay special attention to viscosity; any fluctuations can result in an unsatisfactory finish or cause delays, creating waste. Not ideal for either wallet or planet. By streamlining processes while protecting personnel, these industry leaders deliver consistent coatings on time, every time – with minimal waste.

Most coaters are already aware that viscosity plays a major role in the quality of their process - but you may still be wasting resources due to inconsistencies in your process. Corrective measures to achieve constant viscosity are in place, but there are still issues like these in your process:

These can be costly. But they are also avoidable.

Changing Temperature Occurring in Your Coating Process Impacts Viscosity.

As temperature changes, viscosity changes. This is especially true in coil/sheet/roll coating processes, where it is common for heat to build up. High-speed, high-volume production, chemical properties of the coating materials, properties of the substrate being coated, and inadequate cooling and temperature control in your process can create excessive heat. These changes in temperature create variations in viscosity.

The result of variations of viscosity is costly waste. Even the slightest temperature change happening in and around your process can wreak havoc.

Saint Clair Systems provides a solution: control temperature at the point of application.

Instead of trying to control temperature at the source, we go to the very end of the process and work backwards. We control temperature to within +/-1 degree °F at the final point in the process (the most important point), where your material is applied.

With Saint Clair Systems’ Point-of-Application Technology, Your Process:

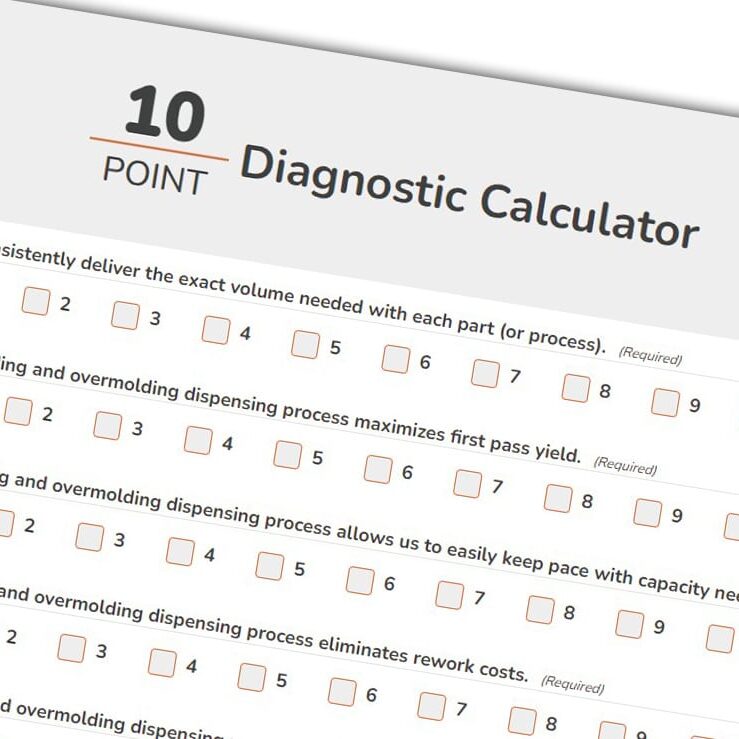

How is temperature impacting your process? We provide FREE tools to help you evaluate it.