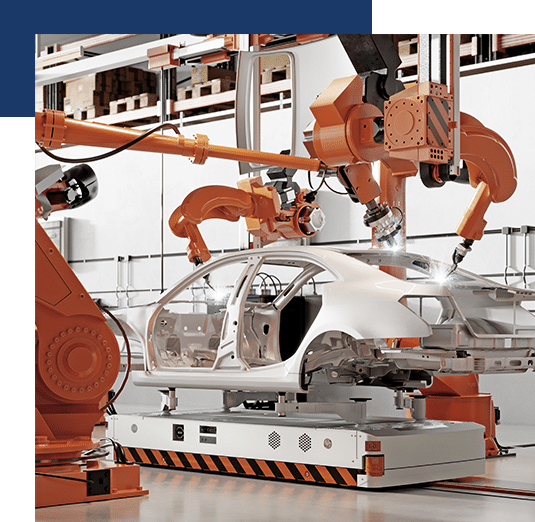

Industry 4.0 is Driving Manufacturers to Invest in Robotics and Automation, and That Includes Applying Lean Manufacturing Principles to Their Automated Fluid Dispensing Systems

These processes involve complex systems that require careful optimization to ensure efficiency and quality. But constantly changing temperature can throw a wrench into even the most advanced systems.

Automating your process may make things easier, but it doesn't protect you from major process variables.

Even minor changes in ambient temperature can drastically alter fluid viscosity. And fluctuations in viscosity lead to imperfections and throughput inconsistencies.

This issue can be frustrating and costly, especially given the significant investment in automation. Saint Clair Systems provides a solution: temperature control at the point of application.

Our advanced temperature control technology is designed to precisely control temperature at the point of application. You can maintain material temperature within 1 degree °F of your desired set point consistently and automatically.

Controlling Material Temperature at the Point of Application Makes Dispensing Reliable.

Consistent viscosity at this level produces game-changing results in your automated process, including things like: