Saint Clair Systems created a disruptive technology that offers unparalleled consistency in fluid dispensing applications across an ever-expanding group of industries.

Temperature Can Change Everything in

Fluid Dispensing Systems

A change in temperature affects viscosity. A change in viscosity in turn impacts the quality and consistency of your output.

By using temperature as a tool to control viscosity, you can achieve consistency, higher process efficiency, increased output, reduced waste and costs, and improved profitability. And our temperature control technology is changing the game.

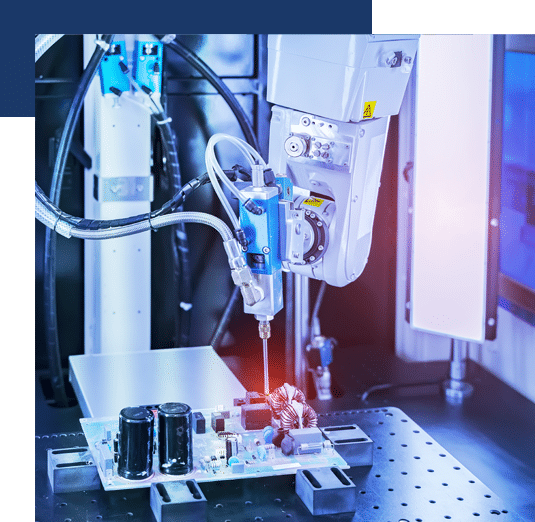

Our proven technology is being used in major manufacturing industries across the board: automotive, food & beverage, coil/sheet/roll coating, aerospace, painting, printing/packaging, robotics/automation, paper/adhesive production, and more.

We can improve the process of any fluid dispense application. The need for temperature and viscosity control at the point of application will grow considerably as more and more dispensing processes are automated.

We encourage you to take a clear-eyed look at how inconsistency in your application is affecting your process. Take advantage of our resources and learn how controlling temperature and viscosity at the point of application may be exactly the solution you need – but didn’t know existed.

Industries We Serve

Click on your industry to see how we can help you refine your fluid dispensing process. Don't see your industry? We offer custom viscosity and temperature control solutions for a wide variety of industries and applications. Contact us today to see how we can help or click button to get started evaluating your process.

How Does Temperature Affect the Dispensing Application in Your Unique Process?

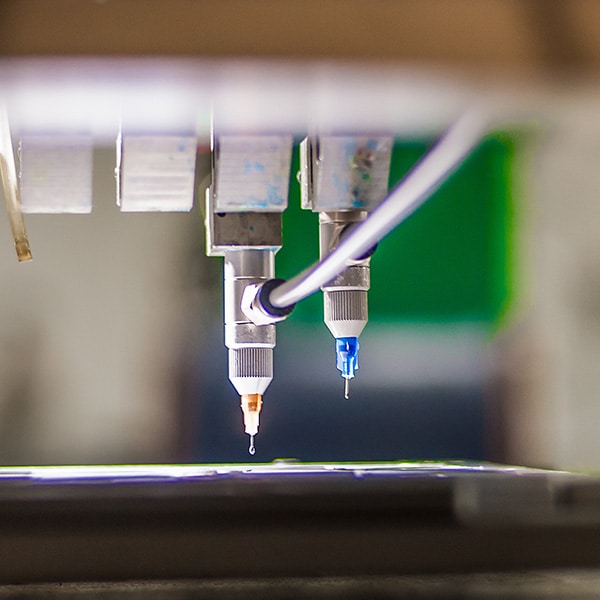

Your robot program is optimized; you know you’re dispensing the same volume every time. Your material supplier assures you’re getting consistent batches.

Why, then, are your applications inconsistent?

It’s not the consistency of your automated system.

It’s not the material supplier, either.

The problem is the process variable of temperature. Temperature fluctuations affect viscosity as liquid makes its journey toward the point of application. And that viscosity affects the consistency of your output.