We recently struck up a conversation with an Account Manager at a major paint supplier. During our conversation, we discussed the batch-to-batch variation of the paints they supply. He said what we often hear from paint suppliers: “Our paints don’t vary much from batch to batch.”

When we asked why their customers often have a different perception, he said, “Most of the variations that they see are self-inflicted.” That prompted us to request a more in-depth follow-up conversation so we could better understand how end users may be unknowingly creating their own batch variations.

His insights were helpful, so we decided to share a summary of them here.

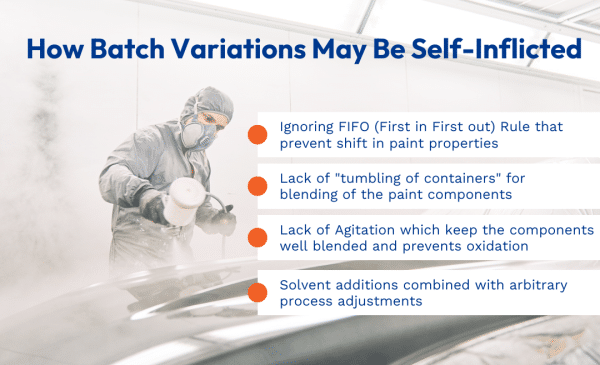

1. Ignoring FIFO

His first observation was that end users sometimes ignore FIFO (First in First out). Paint properties shift over time; the amount of change varies by formulation and is the result of the reactions between the myriad chemicals that make up a specific paint. A small volume of air in the top of each drum also plays a role. Companies that adhere to FIFO are less likely to suffer from changes that take place as those paints age.

2. Not Tumbling

His second observation was that the paint is not often tumbled before it is used. The resin, pigments, and solvents can, and do, separate as the paint sits stagnant. A simple tumbling before using the paint helps blend everything and put the pigment back in suspension to promote consistent color application.

3. Not Agitating

His second observation was that the paint is not often tumbled before it is used. The resin, pigments, and solvents can, and do, separate as the paint sits stagnant. A simple tumbling before using the paint helps blend everything and put the pigment back in suspension to promote consistent color application.

4. Adding Solvent and Other Process Adjustments

His fourth and arguably most significant observation concerned solvent additions combined with arbitrary process adjustments. (For purposes of this summary, we will use solvent to refer to both solvent in solvent-based paints and water in water-borne paints.)

There are times where an operator needs to add solvent. For example, after a long break period, it may be necessary to replenish the solvent that has been lost due to evaporation. However, he observed that paint can be altered to suit an operator’s preference and is often done in conjunction with other process adjustments (i.e. flow rate, atomization, gun speed, etc.). This is where you create issues that ultimately create the appearance of paint batch variation.

If you do need to make a solvent addition, he recommended that you record when you made the addition, how much you added, and why you added it. (Given our knowledge of viscosity change as a function of temperature, we would add temperature to that list.) At a minimum, you are setting up the next operator with a more complete understanding before he or she begins making adjustments or additions.

4. Adding Solvent and Other Process Adjustments

We produced a one-minute video on altering paint that does a nice job highlighting this issue. You can find that video by clicking here. The key point in the video is that if you maintain consistent application conditions, the need to add solvent and make process adjustments can be minimized – or, better yet, eliminated altogether.