When Did Rework Become Part of Your Process? – Part III

In Part II of this series, we looked at examples of countermeasures that become permanent fixtures in our automated fluid dispensing processes. We call them "Touch-up” or “Finesse” or “Final Inspection”. But it doesn’t matter what they’re called; they’re still rework.

In this third installment, we’ll examine why many of the defects that create the need for rework in the first place.

The Temperature Hierarchy

Rework compensates for process variations caused by uncontrolled variables we actually believe to be under control. A good example is temperature.

We go to great lengths to control the ambient temperature in our booth, so we assume that we’ve addressed our temperature problem. But there’s more than one temperature that we need to control.

We call it “The Temperature Hierarchy”.

The Temperature Hierarchy defines the impact that different temperatures have on the dispensing process. They are (in order of priority):

- Substrate temperature

- Fluid temperature

- Air temperature

The reason for this order is simple: thermal mass.

Substrate temperature - the temperature of the part we are dispensing onto - has the most significant impact because it has the greatest thermal mass – usually orders of magnitude greater than the fluid mass.

When the fluid is dispensed onto the part, the substrate changes the temperature of the fluid starting at the interface between the two. If the part is warmer than the fluid being applied, the viscosity at the interface drops and the fluid can move more easily. This can result in run and sag in coatings or spread and slump in sealers and adhesives.

Conversely, if the part is cooler than the fluid being applied, the viscosity at the interface increases and fluid movement is inhibited. In coatings, this can result in gloss and orange peel defects (just to name a few), and tall beads and poor adhesion in sealers and adhesives.

Coating Countermeasures

In finishing operations, rework may take the form of “touch-up” as shown in Figure 1. With this type of rework, an operator sprays critical areas before the robotic cell or examines the wet finish after the robot is done and adds paint wherever it appears necessary.

The problem with this situation is that the operator’s discretion is subjective and actually negates the precision and economy that the robot was installed for.

Usually, the rework in the finishing operation is positioned after cure, as shown in Figure 2. Often called “Final Inspection”, “Buff & Polish”, or the “Finesse Department”, this is where each part is visually inspected for finish quality.

Here, the operator must either accept or reject the part. Often, there is also an option to “fix” the flaws by buffing and polishing areas to remove “dirt” or improve the gloss of the part.

Operators might even sand out defects and send the part back through for repainting (a very costly rework option).

But the worst situation of all is when the part is beyond rework and must be scrapped.

Regardless of the outcome, finesse means that each part must be handled and dispositioned separately. And sometimes, both “touch-up” and “finesse” become part of the process.

Though the curing oven is often cited as the part of the paint shop that sets the maximum throughput, for many plants - if not most - the Finesse Department is the bottleneck operation, limiting throughput and limiting revenue potential.

Sealer & Adhesive Countermeasures

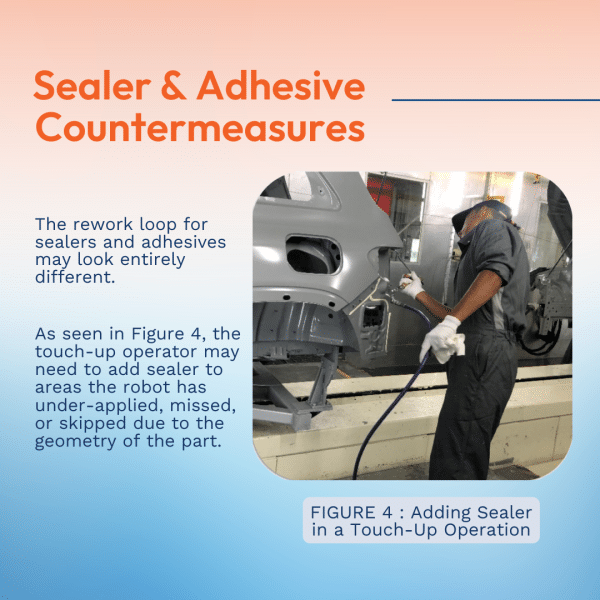

Or, as shown in Figure 4, the touch-up operator may need to add sealer to areas the robot has under-applied, missed, or skipped due to the geometry of the part.

When the part is too warm, the sealer or adhesive can “thin out” at the surface of the part causing it to shear against itself and slide off the surface completely. At that point,the touch-up operator must replace it.

No matter what you call them, these are examples of rework.

Or, as shown in Figure 4, the touch-up operator may need to add sealer to areas the robot has under-applied, missed, or skipped due to the geometry of the part.

When the part is too warm, the sealer or adhesive can “thin out” at the surface of the part causing it to shear against itself and slide off the surface completely. At that point,the touch-up operator must replace it.

No matter what you call them, these are examples of rework.

How Did We Get Here?

The motivating factor behind these efforts is to increase the FPY (First Pass Yield) from the process – usually to meet delivery requirements.

This affects operating costs for things like supplies, floor space, and, of course, personnel (and all of the associated overhead). This directly impacts profitability.

Often-overlooked is the impact on the competitive position in the marketplace – the ability to maintain current business and to add new business – which ultimately affects the potential for growth – and even survival.

Acceptance is the First Step

As with any intervention, the first step is to recognize and accept these things for what they are: rework.

So, now we’ve identified some of the points of rework in our process. In Part III of this series we’ll discuss the real root causes of these problems – and how to solve them.