The Ultimate Guide to Flexographic Printing

Flexographic printing has been around since the 1920s, but really became popular in the 1940s, when more industries began to use the process on an increasing number of substrates.

Today, flexographic printing is known across the world as one of the most affordable, high-quality printing processes available – and it has environmental advantages to boot.

So without further ado, here's everything you need to know about how it works and why so many people use it.

What is Flexographic Printing?

Flexographic printing is a printing method that allows the printer to print on flexible substrates because the process uses flexible (rather than traditionally rigid) raised-image printing plates. These plates are attached to cylinders, and then inked by a roll that carries low-viscosity inks onto the plate, which then transfers it onto the substrate. Typically, each plate transfers a single color to the substrate, and the substrate goes through multiple stations to print the completed color image.

Applications for Flexographic Printing

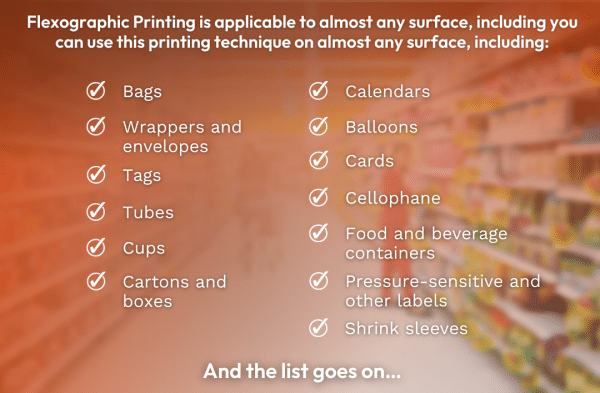

One of the best things about flexographic printing is how incredibly versatile it is. Though it’s most commonly used on non-porous substrates, you can use this printing technique on almost any surface, including:

- Bags

- Wrappers and envelopes

- Tags

- Tubes

- Cups

- Cartons and boxes

- Calendars

- Balloons

- Cards

- Cellophane

- Food and beverage containers

- Pressure-sensitive and other labels

- Shrink sleeves

And the list goes on…

As such, flexographic printing machine is used today to print on anything – shopping bags, milk cartons, wallpaper, pet food bags, and so much more.

Other Benefits and Advantages of Flexographic Printing

Printing with the flexographic process involves using continuous webs of substrate. That means you can print at very high speeds without worrying about interruptions or stoppages to change it. On top of that, flexography also has the benefit of compatibility with a wide range of inks, especially when compared to lithographic printing, including solvent, oil, water-based, and 100% solids UV cure inks.

Because you can use water-based and UV cure inks with this printing process, it’s also more eco-friendly than other printing methods. Plus, the low-viscosity inks have a faster drying time (UV cure is essentially instantaneous!), and this results in quicker production times, higher throughput, and lower costs.

Flexographic printing is the fastest-growing printing process in the world, largely because of its high quality, high efficiency, versatility, low costs, and environmental benefits. It’s also immensely popular because it was designed specifically for printing on flexible substrates and materials.

Flexographic printing is worth looking into. It can save you time and money and optimize your operations.