Imagine that you walk into McDonald’s, grab a super-size Coke, and notice something isn’t right. As you look closer, you realize the “golden arches” aren’t so golden — they’re more of a green-ish color.

Would you be uneasy?

Later in the day, you grab a Coke from the vending machine in your office. But, when you pull it from the vending tray, instead of the familiar, bold “Coke red”, the can is more of a pinkish color.

Would you drink it?

On the way home, you stop by the grocery store to buy a case of Coke, but when you get to the shelf, the cardboard packages range from pinkish-red to maroon. Would you question the store’s stock rotation practices and start checking dates? Would you just grab the one that seemed like the correct shade of red?

Or would you just buy Pepsi instead?

Of course, these are hypothetical situations. But they demonstrate how important color is to a brand. Coca-Cola red, like McDonald’s golden-yellow, is instantly recognizable. McDonald’s and The Coca-Cola Company understand this – and they take great pains to ensure their brand images are consistent.

But what if they didn’t?

What if every McDonald’s cup had a slightly different shade of yellow? What if every Coca-Cola package varied in its shade of red? Aside from adding confusion to the buying process (something no company ever wants to do), this could damage the consumer’s perception of the company. Damage a company’s image enough, and it will invariably hurt their profitability.

In short, exact color matching is critically important when it comes to the recognition of a brand. That means printers have to pay special attention to maintaining color quality and consistency in high-volume, repetitive production operations for things like beverage cups, cans, shelf packaging, displays, advertisements, and more.

Why?

Because businesses like McDonald’s and The Coca-Cola Company reject products every day that are even slightly inconsistent with their brand colors.

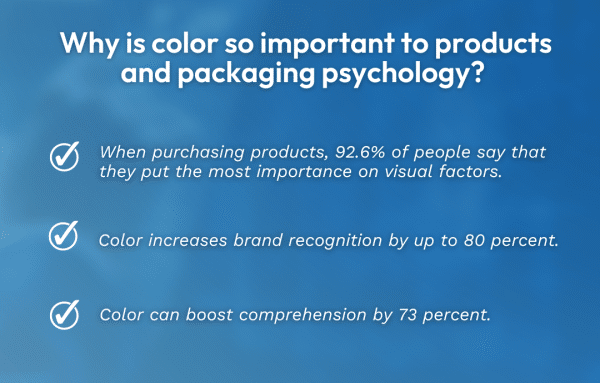

But why is color so important to product and packaging psychology?

Here are some interesting statistics on the issue of color and brand, reported by Jill Morton of Colorcom:

- When purchasing products, 92.6 percent of people say that they put the most importance on visual factors.

- Color increases brand recognition by up to 80 percent.

- Color can boost comprehension by 73 percent.

It seems that human beings are physiologically and psychologically wired to pay attention to color!

And that’s no accident. There are biological reasons for recognizing color — seeing color helps living creatures differentiate between objects and determine whether they represent predators, mates, or food!

According to a WIRED magazine article (based on a study published in the journal Science), most monkeys and apes only have two-color vision and perceive their environment as “greyish and slightly red-hued.” Early human ancestors, on the other hand, “regained three-color vision because spotting fresh fruit and immature leaves led to a more nutritious diet.”

In other words: humans see and recognize color because it aids in our survival as a species. And while you certainly don’t need McDonald’s fast food or a can of Coke to survive, it makes sense that their packaging colors would take advantage of something so fundamentally important to the human brain.

The bottom line…

The moral of the story is that printers have a very fine margin of error when it comes to keeping color consistent for product packaging. That requires meticulous ink management — lest the end product feature McDonald’s “green-ish arches” or “Coca-Cola pink” (just toss them in the scrap bin — we all know they’re not going anywhere!).

Proper ink management can be a difficult process; evaporation can vary viscosity and pH. (So can adding stabilizers and defoamers, for that matter.) Changes in temperature can affect viscosity, but they also affect the evaporation rate.

Trying to compensate by making manual adjustments in the middle of a run is fraught with opportunities for disaster..

Saint Clair Systems can help with that. Click here to find out more about our point-of-application solutions.